How to make vinyl banners?

Vinyl banners are a very common form of offline advertising. They can certainly be very profitable for a printing company. For a printing business, it is estimated that even up to 40% of their profit, comes from custom made vinyl banners. Therefore, vinyl banners are not only very popular but also very profitable.

The market for vinyl banners is extremely large. They can be sold to anyone, from small startup businesses, household customers, and government facilities, to corporate giants. In order to become a successful profitable business, learning how to produce, sell and install banners correctly is crucial.

In order to help you out, we will guide you through the equipment, tools, and supplies needed, as well as cover a few other important tips.

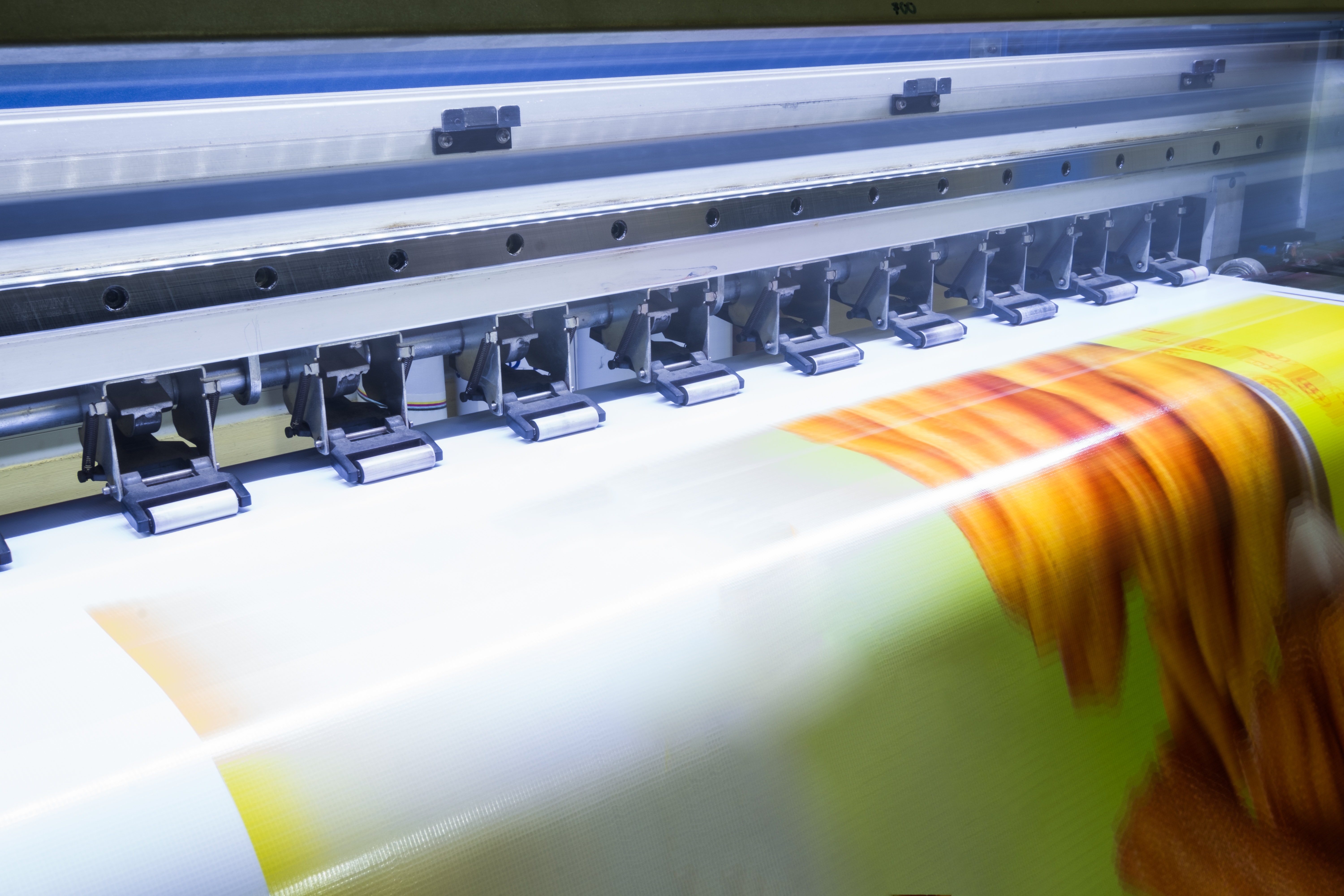

The most common and the best form of printing vinyl banners is digital printing. You will need a good PC and graphic design software. The software is, actually, extremely important. It can make or break the quality of your banners. Some of the best software on the market are Flexi-Sign, CorelDRAW, Master Plus, and LXI Master.

Besides having good software, you will most certainly need high-quality printers. You will need digital printers. Printers are an expensive investment but, in the long run, will not only give you back your invested money but also generate a whole lot of profit for your business. They also reduce material costs because they transfer a digital image right onto the rolls of vinyl. There are also other types of printers on the market, such as UV printers, but they are extremely costly. Perhaps, you can consider purchasing one of those once your business is standing strongly on its feet.

Once you are equipped with the basic tools and equipment, you will need additional specialized banner-making hardware, for finishing options. Customers often prefer their banners to be grommeted, hemmed, and/or have pole pockets installed.

Grommet machines are not that expensive. You can start off by purchasing a simple hand device for grommets, but if you would like to save yourself time and extra workforce, you can invest in an automated grommet machine. There’s a variety of grommet machines on the market, but we recommend Stimson and Super Ace.

Hems are, most commonly, heat welded edges. They can also be sawn, but you would need a sewing machine for your banners, which can be costly and time-consuming. Heat welded hems are a lot easier and faster to do, but just as good. Therefore, you might want to look into purchasing a hemming machine. This machine will not only create hems for you but can also be used to create pole pockets. One such machine is Banner Pro.

The next thing that you will need, and which you cannot have banners without, is vinyl banner rolls. They are blank vinyl canvases, typically up to 150 ft long, and, surprisingly, they aren’t so costly. They can come in a variety of “weights” (vinyl thickness), but we recommend that you purchase 13 and 18 oz. vinyl. The 13oz vinyl is the standard “indoor” (also used outdoors) material, and the 18oz is the more “heavy duty”, and outdoor, material. Also, the finish of the vinyl material can be matte or glossy. You should opt for both, so you can give a choice to your customers. Most customers will order matte banners, as they don’t flash back in pictures. Especially if your customer will be using their banner as a backdrop.

As for the banner display, we recommend that you equip your inventory with banner stands. They can be retractable (pull up) or X-stands. We suggest both. Retractable banner stands are usually sturdier, and can typically be used outdoors, however, some weight is needed to hold them down. X-Stands are usually used indoors as they are very lightweight.

Finally, let’s discuss the pricing. Typically, vinyl banners go anywhere between $2 and $8 per square foot, which doesn’t include a design fee. It is up to you if you will decide to charge your customers for a custom design, or not. Single color banners or two color banners sell for a cheaper price than full color banners. We suggest that you do some more research on the banner printing market, and their prices, both in your local area, or further (if you decide to become an online business vs a local shop), before you settle on the final prices

Did you find it helpful?

LIKE

DISLIKE

Comments